Table of Contents

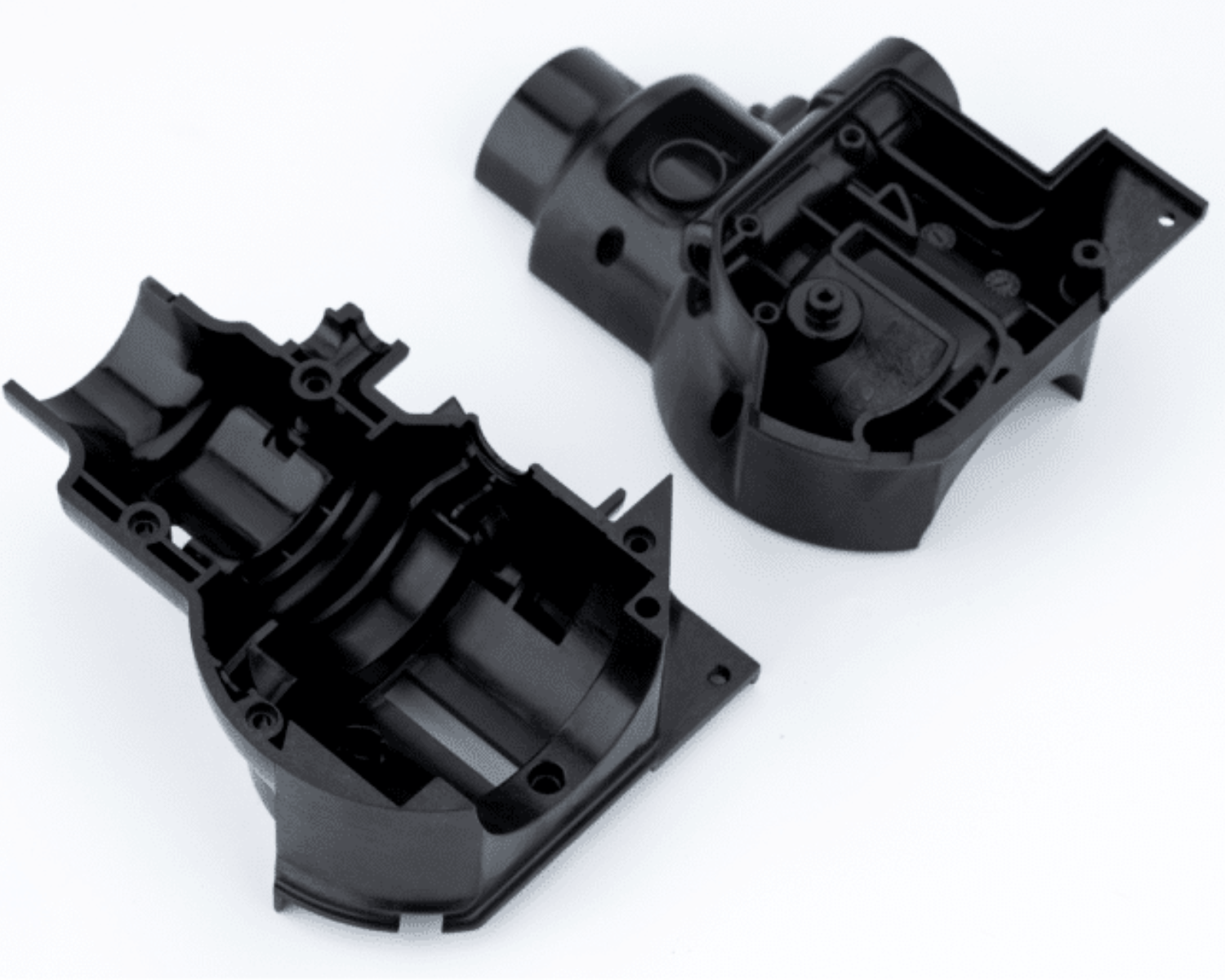

When it comes to the plastic industry, maybe the most important consideration is injection molding tolerances. Ignoring tolerances in the design phase could lead to injection molded parts that cannot be assembled, do not function optimally, or do not work properly in the field. More tolerances result in costlier manufacturing with no added benefit to the final product.

This guide should be particularly useful to engineers, designers, and product managers who are dealing with the challenges of injection mold dimension. We will define tolerances and the different categories you must be familiar with, the role of material selection in determining precision, the variables that shape the outcome of your plastic injection molded parts.

What Are Injection Molding Tolerances?

No matter the production technique, there bound to be small variations between the CAD model and molded object, which is what is meant by injection molding tolerances. Depending on the magnitude and direction of the variance, the molded object could be classified as either non-conforming or conforming. A tolerance indicates how much variance is acceptable. In the injection molding world, tolerances help mold makers determine how close or precise they should be to goals, since no molding process is perfect.

You can think of tolerances this way: assume you had a puzzle where all pieces had to be a perfectly identical size. If they weren’t, one or two pieces would be impossible to fit together.

Maybe the piece that is too big is just a tiny fraction too big but the piece that needs to be connected to it is too small. In addition to mold variations, this can happen to a small degree multiple times, resulting in a puzzle that simply cannot be assembled.

The tolerances help to ensure that the molded variation will still be functional. In this context, it is also important to realize that accuracy increases costs. A tighter tolerance will increase costs since it will require more accurate tooling to be used, which could require more expensive materials, and more expensive process control. A loose tolerance will be more preferable to the manufacturer since it will result in lower costs.

Types of Injection Molding Tolerances

Within every engineering sector, Injection molding parts also has a set of guidelines governing the tolerances, which in this case includes two sectors: the dimensions tolerances, and the tolerances of the geometry and how this interacts with each other.

Dimensional Tolerances

The tolerances associated with dimensions tends to be the most common in engineering as it relates to the difference in a particular characteristic, mostly the dimensions, to the surrounding or compared sample. It mostly occurs within the variables of height, width, and length, as well as any holes that may be present within the sample.

For example, there may be a requirement that involves a housing plastic component of a sample that involves a sample length of around 50mm with a tolerance of around 0.1mm. Any sample that has a length between 49.9mm and 50.1mm as it would be within the acceptable ranges of the quality control level. Any component that has a 50.2mm would be beyond the acceptable ranges.

Geometric Dimensioning and Tolerancing (GD&T)

While dimensional tolerances cover size, GD&T covers shape and orientation. As parts become more complex, knowing the exact size isn’t enough; you also need to know if the geometry is correct.

- Flatness:This measures how flat a surface is. This is critical for sealing surfaces or parts that must slide against one another.

- Straightness:This ensures that a linear feature, like the edge of a box or a pin, does not bow or warp beyond an acceptable limit.

- Concentricity:This is vital for cylindrical parts, such as tubes or gears. It ensures that two circular features share the same center axis.

If you are designing a cylindrical cap that screws onto a bottle, simple dimensional tolerances might ensure the diameter is correct. However, GD&T (specifically concentricity) ensures the threads align perfectly with the bottle so the cap screws on smoothly.

How Material Choice Affects Injection Molding Tolerances

One of the biggest variables in achieving precision is the resin itself. Different polymers behave differently when melted and cooled, which directly impacts the dimensional accuracy of injection molded parts.

Shrinkage Rate

All plastics will cool from a molten state to a solid state, and as they do, they will all shrink. However, they do not shrink to the same extent. The “shrinkage rate” is how much material will contract during the cooling process.

Because a high shrink rate leads to a greater variation in tolerances, holding materials with a high shrinkage rate to a tight tolerance can be more challenging. Amorphous plastics (like ABS) are dimensionally stable and shrink less than semi-crystalline plastics (like Polypropylene or Nylon), which shrink a lot, making it harder to hold the same high tolerance.

Typical Shrinkage Rates of Common Materials:

Material | Structure | Typical Shrinkage Rate |

ABS | Amorphous | 0.4% – 0.8% |

Polycarbonate (PC) | Amorphous | 0.5% – 0.7% |

Nylon (PA6) | Semi-Crystalline | 0.7% – 2.0% |

Polypropylene (PP) | Semi-Crystalline | 1.0% – 3.0% |

Material Stability

Aside from the initial shrinkage of the material, the engineers also have to look at the environmental stability of the material. Some materials are hygroscopic, which means that they absorb moisture from the air and, post-molding, swell and change dimension. An example of that is nylon.

If your injection molding tolerance requirement is at the extreme limit (e.g. aerospace and medical connectors), you may have to choose some of the engineering high-performance materials, such as PEEK, or Liquid Crystal Polymer (LCP), or reinforced standard resins with glass fiber. Glass filled nylons, for example, shink a lot less than unfilled nylons because the glass fiber provides internal structure and that structure resists contraction.

Other Factors That Influence Tolerances

While the material is a major player, it isn’t the only factor. The machinery, the mold, and the design itself all contribute to the accuracy of your injection molding parts.

Design of the Mold

Precision starts with the tool. For high volume production, high-quality steel molds hold tolerances better than aluminum molds. In addition, the mold design also affects the precision of the produced parts.

Cooling Uniformity

Cooling uniformity is required if one side of the part cools faster than the other, the part will warp causing it to be out of the required tolerances.

Design of the Part Impact

Every part has to have some level of complexity to be in design, however some designs are more easier than the other to be able to be manufactured.

Warpage caused due to aka and cooling

If there is a non uniform wall thickness, the part can warp due to the thickness of one wall compared to the others having a different thickness. The best way to avoid having dimensional variation is having uniform walls.

Design Complexity

Complex design features can cause additional modifications to be made to the design. An example of additional modifications are the features leading to a construction or installation of sliding components.

Domiant Processing Conditions

To be able to process the marine accurate, the controls, injection pressure, melting temperature of the material and holding time, have to be dialed in accurately.

Conclusion

Specifying injection Molding tolerances is a finding act as it requires to be balanced, A tolerance on a drawing translates to cost and a manufacturing material.

In the end, the most effective method for achieving the proper fit is teamwork. Do not postpone discussing tolerances until the design is complete. Contact your manufacturing partner in the early design stages. To ensure your design is attainable in a cost-effective manner, they may help you refine your material choices, and geometry.

Ready to begin your next project? Contact our engineering team today for a free review of your design for manufacturability.

Frequently Asked Questions (FAQ)

Q:What are standard injection molding tolerances?

A: While there are no universal standards, the most popular tolerances are the DIN 16901 and the ISO 20457 standards. As an estimate, the commercial tolerances are ± 0.005 inches ( 0.127 mm ) for the first inch and ±0.002 inches for every additional inch. However, the range could vary substantially depending on the material.

Q: What are the tolerances for plastic parts?

A: For plastic components, the tolerances are assigned by determining the primary functional dimensions ( fit and form ) and then defining an upper and lower threshold on the dimensions. Usually, these are documented on the 2D technical drawing or captured in the CAD metadata.

Q: Why are tolerances for injection molding looser than CNC machining?

A: With CNC machining, the material is removed from a solid block, which is a very steady process that is not prone to thermal shrinkage. In contrast, injection molding works by first heating the plastic, then melting, and finally cooling. All of which, create enough variables to make consistent and affordable tight tolerances extremely difficult.