Table of Contents

Take a moment to look at the space around you. Take notice of the plastic materials that everywhere. Look at the case of the computer screen and think of the plastic buttons below the screen and the plastic bottle of water. The plastic bottle and the car dashboard are everywhere you look and are made from plastic materials. They all share a common origin. They are all made from a process called plastic injection.

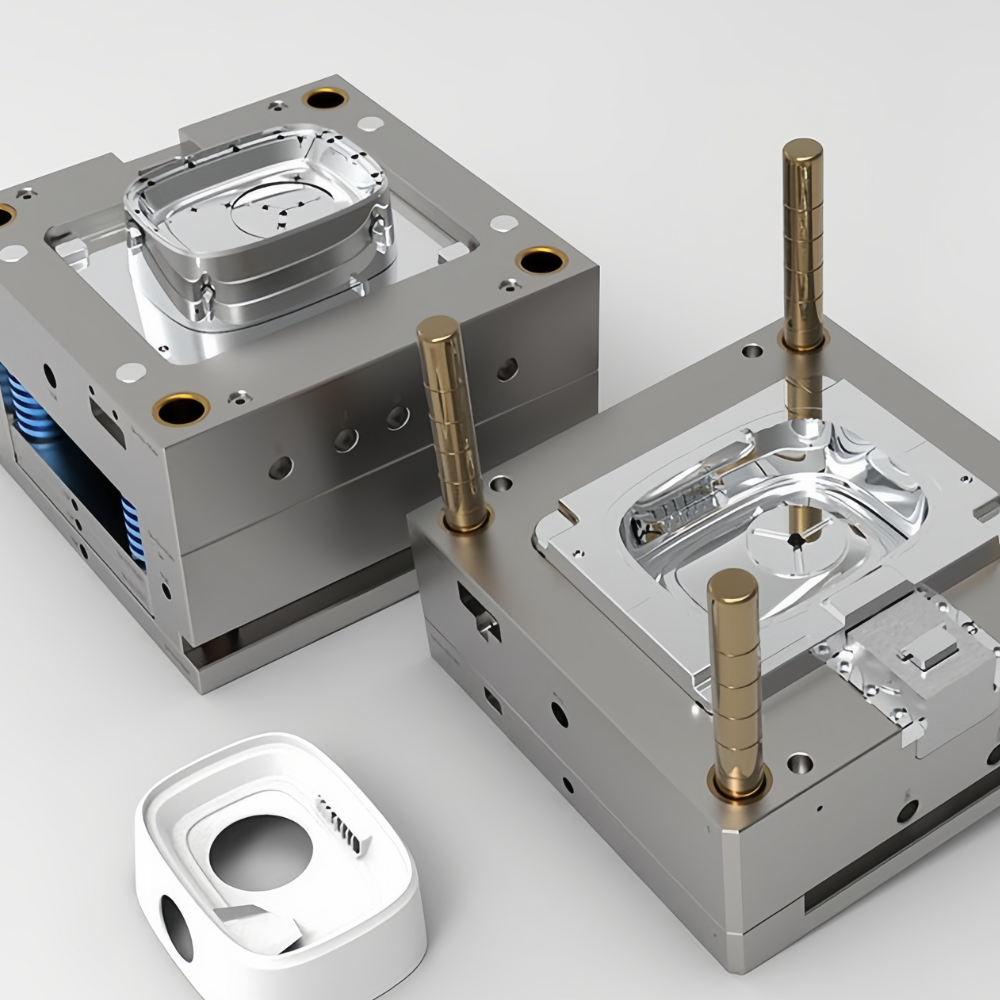

Fundamentally, plastic injection process is a method of manufacturing that involves the injection of melted thermoplastic resin into a mold, where it is kept at a high pressure. The mold is then allowed to cool and harden.

This article will detail the 10 most important plastic injection molding, which is the reason why it is considered the best and most useful means of reproducing high quality plastic components or products.

1. High-Efficiency Production

Speed is critical in mass production. One of the nigh unbeatable MVPs of production is molding. When an initial mold is built and the machine is set up, molding is smooth sailing.

The simplicity and size of the mold will determine the time per cycle, some lasting only 15 to 30 seconds. With how rapid and plentiful, manufacturers can make thousands of parts per hour. Multi-cavity molds can actually increase the productivity to multiple parts per cycle. With the need to quickly scale production in many businesses, few other methods can compete to meet this need.

2. Complex Part Design with Precision

There exists an assumption that products made at high volumes will have uncomplicated designs. Plastic injection molding, however, contradicts that assumption. This production technique can accommodate complex shapes which are often impossible or costly to reproduce with other methods such as CNC machining.

The extreme pressure of the injected plastic leads to the material being tightly packed to the walls of the mold, allowing the production of complex designs, microfeatures, and detailed shapes. Injection molding can produce intricate designs in the end products, such as in the case of detailed medical device gears or elaborate electronic housings.

3. Enhanced Strength and Durability

Soft, pliable components made out of plastic easily can be made tough and rigid. Components made out of plastic can easily be made to be tough and rigid, and in areas such as automotive and construction, that need to be tough and rigid. The great thing about injection molding is that the modificable materials have their properties modified and enhanced while in the molding process.

Molding material that the manufacturers use can have fillers added to them. During the molding process, those fillers can greatly enhance the structural integrity of the overall part and are able to decrease the overall density of the plastic. This opens up great opportunities for engineers to design and build parts that are lightweight, and that are durable and tough which is the perfect combination for any industry that focuses on performance.

4. Flexibility in Material and Color

The sheer range of materials that can be covered by the term ‘plastic’ is astonishing. Injection molding gives you access to thousands of different resins. Every project can demand something different: a rigid polymer that is highly heat resistant, a flexible rubbery material, a food-safe plastic, and so on. There is a resin to meet all of those needs.

The flexibility of the resin used is not the only contributing factor to the aesthetics. Changing the color of the plastic can be done quite easily and does not call for a new mold to be built. Furthermore, methods such as co-injection molding allow different materials to be used together in a single cycle. This means that a part can have a soft-touch exterior over a hard rigid core, and all be produced in an efficient cycle.

5. Automated Manufacturing = Low Labor Costs

Managing costs is an essential part of the process of production and manufacturing. Labor is one of the biggest costs in the production process. The good thing is plastic injection molding is an automated process. Most of the labor that needs to be done is done by machines and robotics in the injections, cooling, and ejection processes of molding.

Lessens overhead costs as well as general costs as the processes done by labor worker are done by machines. More of the manufacturing process is not only cheaper, but also more efficient.

6. Reduced Waste and Sustainability

As we enter a corporate culture where sustainability is at the forefront, the processes used in manufacturing are increasingly criticized. There are traditional methods of machining as well as ‘subtractive’ manufacturing. This process essentially cuts away a material block to reveal the necessary component. This traditional method, as the name of the method suggests, creates a lot of waste.

By contrast, in-mold injection is, by nature, additive. It uses the exact amount of material necessary to fill a mold. There are also sprues and runners that exit a cube of some excess material, but these do not necessarily create waste. In many facilities, this excess plastic is re-ground and recycled into the process. This is a closed-loop system that results in little to no waste generation and, thus, is sustainable during in-mold injection.

7. Exceptional Design Flexibility

Although the majority of your spending should go towards the design of the mold, the final product gives you relief because of the design’s flexibility. For example, molds can be integrated with modules that can be replaced easily, such as cores.

If an adjustment is required, like adding an updated logo or modifying the adjustment of a clip, the entire mold can be saved and a tool can be altered or inserted, avoiding the total loss of the mold. This flexibility is one of the main reasons that a return on your spending on tooling can be justified.

8. Tight Tolerances

In manufacturing, “tolerance” refers to how much a physical dimension can vary. For example, there are some assemblies, such as a snap-fit automotive dashboard or the gears of a printer, that are constrained as to how much the parts can vary. These assemblies require high precision.

With the advancements of modern injection molding, as well as high quality molds, tolerances of less than +/- .005 inches are common. At this precision, all parts of the assembly function as intended and the risks of failing assemblies or returns from the customer are mitigated.

9. Product Consistency

It is a matter of brand reliability. Consistency is a business hallmark. If a customer purchases a product today, they expect it to be of the same quality as the product they purchased a year ago.

Injection molding provides unrivaled part-to-part consistency. After the mold is made, and parameters of the process are set, the second part made will be the same as the tenth part, and the same as the tenth thousandth part. This level of repeatability is critical for quality assurance, and it guarantees that high quantities of production will not lead to a decrease in quality.

10. Multiple Finishes Available

The treatment of the faces of plastic components starts with the design of the mold and is finished with painting the component. With an injection molding machine, the finish can be applied while the component is being molded and injected.

A mold can be designed to create components that have a matte finish, high gloss sheen, and/or specific patterns for gripping on the component. In addition, the design of the mold can be configured to include letters, logos, and/or instructions, which can be engraved in the mold to be saved. The addition of these features into the mold saves time and money for the injection mold manufacturer.

Is Plastic Injection Molding Right for Your Project?

Just how much of an impact has plastic injection molding had on modern manufacturing? There is an upfront investment for tooling, but the long term benefits include high speed, low cost per unit, almost unbelievable precision, and versatility of materials to an extent that makes plastic injection molding the most affordable option for mass production.

If you’re attempting to layer production, plastic injection molding is most likely your best option. However, the best first step is assessing your design and volume needs.

Designed plastic injection molding that puts your vision into reality. Contact us regarding your upcoming project to get a quotation or consultation with our engineers to determine how best your injection molding should fit your needs.

Frequently Asked Questions

Q: How much is plastic injection molding?

A: lThough the process is labor- and time-intensive at the beginning, in the long run, the cost per unit is very low. For small units, the pricing per unit is more expensive, however, for large units, the overall cost is very economical. The reason is the startup high cost for the design and production of the mold.

Q: What can be used for injection molding?

A: Injection molding can be used with many types of thermoplastics like ABS, Polycarbonate, Polypropylene, Nylon, and Acrylic. The variety of options is in regard to the properties of the final product and the goal of the production such as flexibility, durability, and heat resistance.

Q: How long does it take to design a mold?

A: The production of a mold can take time due to the design. The more intricate a mesh of a mold is and the more advanced it is in terms of geometry, the design process will take more time. For simple types of molds, it can take a few weeks to design, however, for more complex multi-box molds it can take months.